Custom Precision CNC Turned Parts From China

Your reliable precision cnc turning service partner in China, creating complex geometries and features on plastic and metal parts for prototypes and low-volume manufacturing.

- No MOQ!

- Tight Tolerances: ±0.005mm

- Fast Turnaround From 3 - 20 days

- 20+ Surface Finishes Options

- 50+ Metals & Plastic Materials Choose

PARTMFG: Your Trusted High Quality CNC Turned Parts Manufacturer In China

At Densen, our CNC turning services deliver high-precision, cost-effective solutions for machining cylindrical and rotational parts. Using advanced CNC turning centers, we can achieve exceptional tolerances, fine surface finishes, and complex geometries on a variety of materials, including metals and plastics.

Our expert team works with your designs to create parts with tight tolerances and consistent results. Whether you need simple shafts, complex fittings, or custom turned components, we ensure the highest quality and precision at every stage of production.

With the capability to handle both prototypes and large-volume runs, we provide flexible, reliable, and quick turnaround times, meeting your needs for both one-off parts and large production runs. Experience the precision and reliability of CNC turning with PartMFG, where your specifications are our priority.

CNC Turning Tolerances

At Densen, we follow ISO 2768 (medium) for plastics and ISO 2768 (fine) for metals. We consistently achieve CNC tolerances from ±0.005″ (±0.125mm) to ±0.002″ (±0.05mm), ensuring precision across applications.

For tighter tolerances, we work from your 2D technical drawings to meet exact specifications, ensuring optimal accuracy and performance.

Type

Tolerance

Standard Tolerances

Metals: ISO 2768-f / Plastics: ISO 2768-m

Maximum Part Size

7.9×19.7 inch

Minimum Part Size

0.079×0.079 inch

Minimum Feature Size

Φ 0.00197 inch

Linear Dimension

+/- 0.001 inch

Hole Diameters(Not Reamed)

+/- 0.001 inch

Shaft Diameters

+/- 0.001 inch

Overview: What is CNC Turning?

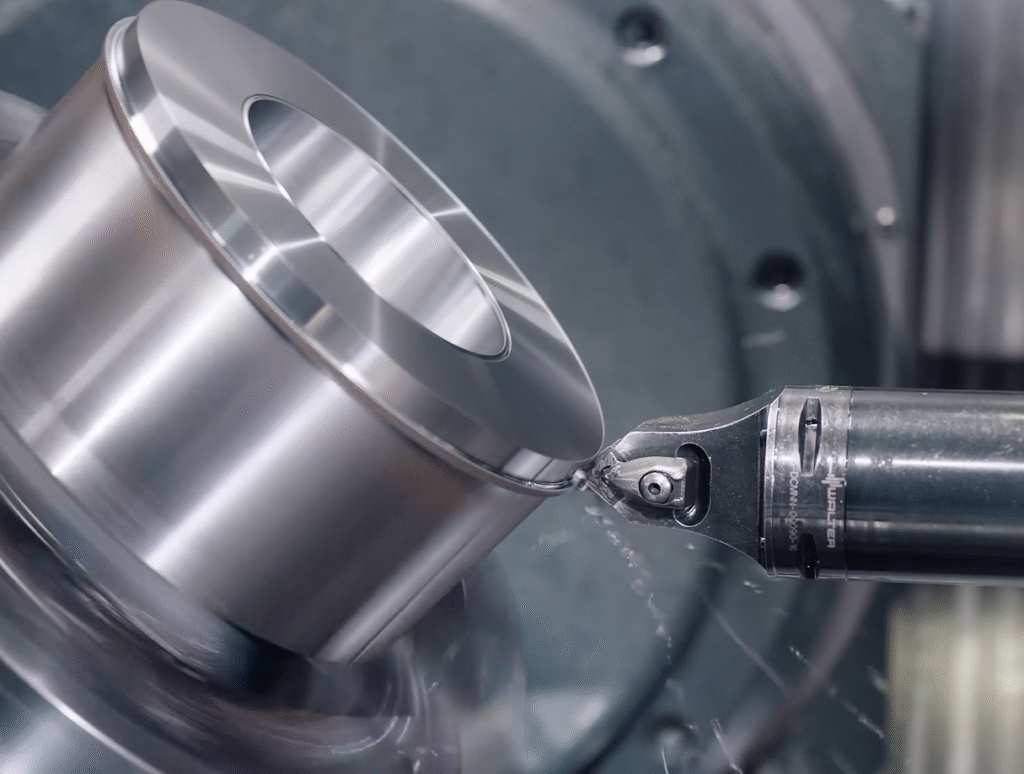

CNC turning is a manufacturing process used to create cylindrical parts by rotating the workpiece against a stationary cutting tool. The tool removes material to achieve the desired shape and dimensions.

Turning involves holding the workpiece in a horizontally-mounted, adjustable spindle. As the workpiece rotates, various cutting tools are applied to the piece to create circular shapes and features like rings, grooves, slots, contours, radii, internal bores and threads. On our Haas turning mills, an extra axis of movement allows us to work perpendicular to the lathe spindle for making square faces or boring holes. This opens up many new machining possibilities.

Turning is used for any rotationally symmetrical shape, to remove material quickly while leaving an excellent surface finish that sometimes requires no post-processing.

The Advantages Of CNC Turning Services

- Cylindrical Parts

CNC turning is ideal for producing round or cylindrical parts with high speed and precision.

- Surface Finish

Turning provides excellent surface finishes, often eliminating the need for additional finishing processes.

- Material Versatility

CNC turning support a wide range of materials, including both metals and plastics.

- Taper and Thread Cuttin

Easily produces tapered features and threads, which can be complex in milling.

- High Production Rates

Capable of rapid production, especially for high-volume runs of similar parts.